Toyota sets up North American Hydrogen Headquarters in California

In an effort to boost the development of fuel cell and additional hydrogen-related products and technology, Toyota Motor North America (TMNA) has renamed the TMNA R&D California office as its new North American Hydrogen Headquarters (H2HQ).

The office workspace at the new H2HQ was recently redesigned for its teams working from research and development to commercialization, planning and sales of hydrogen-related products and technologies in the North American region.

Last year, Toyota reorganized its hydrogen business in Japan and called the facility as "Hydrogen Factory" with the idea to bring all hydrogen-related work under one location and accelerate customer-oriented product development and production in fuel cells.

Toyota Motor Europe also followed suit, announcing its own "Hydrogen Factory" with the aim to further grow Toyota's hydrogen business and stimulate wider roll-out of hydrogen ecosystems and infrastructure across European markets.

"Toyota has developed hydrogen fuel cell electric solutions for more than three decades, and we will continue to advance this scalable, zero-emission technology as part of our electrified portfolio," said Ted Ogawa, President and CEO, Toyota Motor North America.

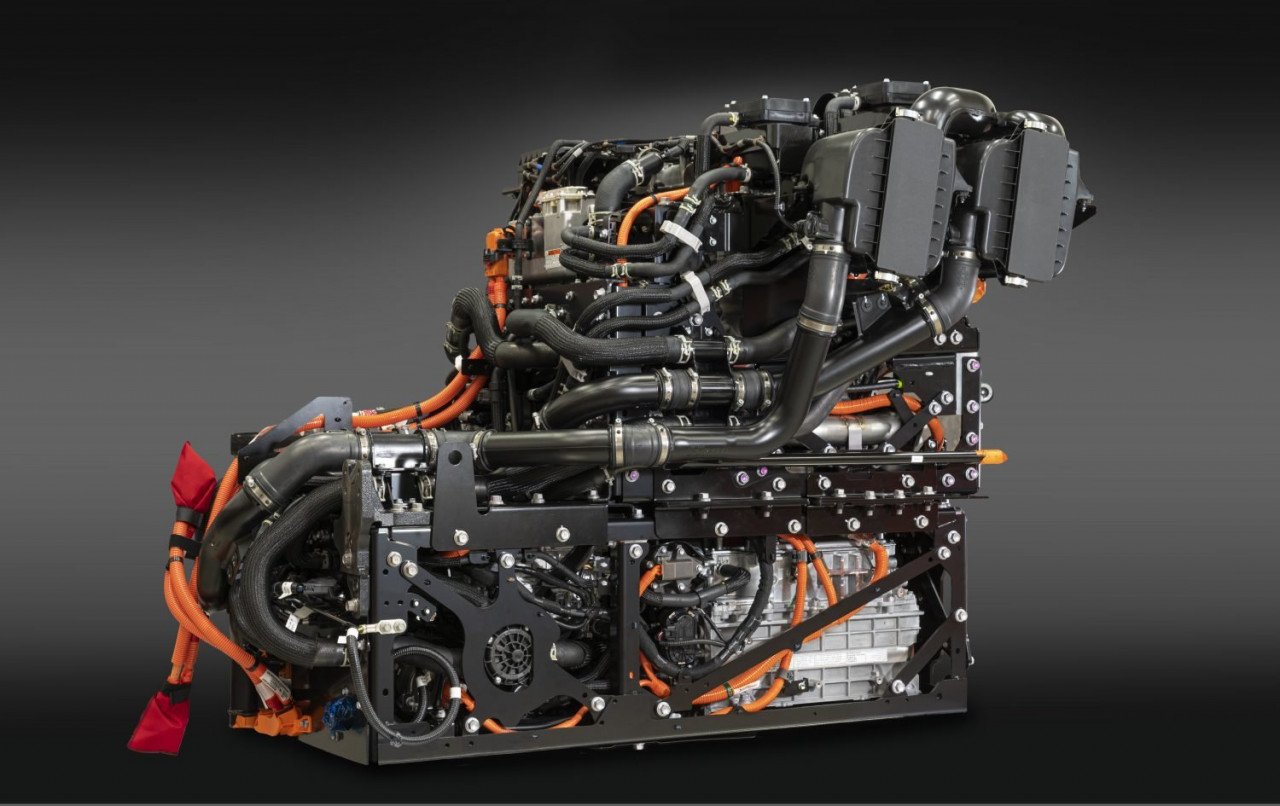

Toyota secures CARB's nod for its heavy-duty Hydrogen Fuel Cell Electric powertrain

"Renaming this facility as North American Hydrogen Headquarters represents our leadership in fuel cell development creating real-world products to help reduce carbon emissions", he added.

According to the company, the H2HQ will drive North American-led hydrogen initiatives and support the localization of global hydrogen-related technologies and products including light-duty fuel cell applications, heavy-duty fuel cell opportunities, stationary fuel cell power generation, port vehicle applications and so on.

The facility already boasts R&D assets, including Toyota's largest 1.2 MW dynamometer, a scalable test bench for stationary applications, and a hydrogen fueling station capable of providing fuel for both light- and heavy-duty vehicles. It is expected to host several new projects in the coming years.

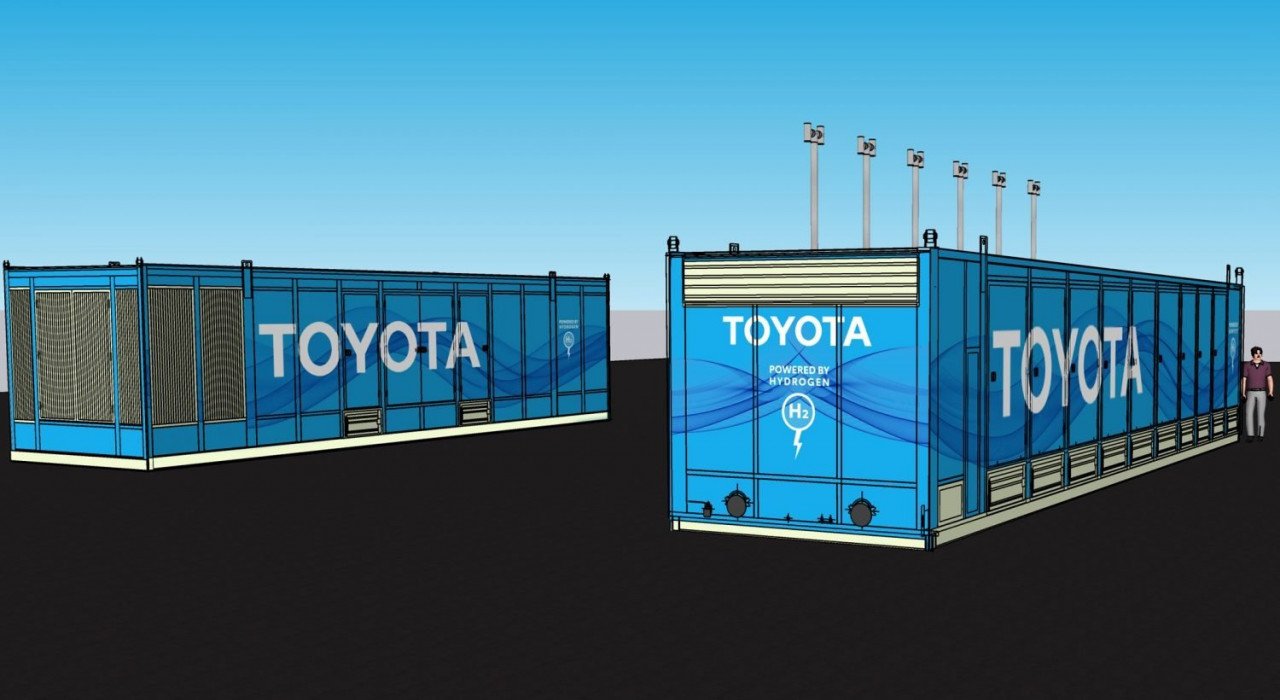

Construction of a flexible microgrid for the H2HQ is also on, featuring a 230-kW solar photovoltaic system, a 1-MW stationary proton exchange membrane (PEM) fuel cell generator, 325-kW solid oxide fuel cell (SOFC), and an onsite 500-kWh battery energy storage system.

The microgrid is designed to support the campus' energy needs, allowing it the ability to operate off-grid. The system is expected to be fully operational by 2026.