Battery recycling in India: Unlocking the value in used EV batteries

The electric vehicle industry in India has reached an inflection point.

In FY 2023, over a million EVs were sold in India accounting for 6.38 percent of the total auto sales in the country, and a record 50 percent year-on-year increase compared to FY 2022.

As a growing number of Indian consumers embrace EVs, by the end of the decade, we're likely to see an influx of first-generation, end-of-life, EV batteries. A study by the Confederation of Indian Industry (CII) suggests that ~72 GWh to 81 GWh or ~447 – 517 thousand tons of waste batteries would reach recycling firms from 2022 to 2030.

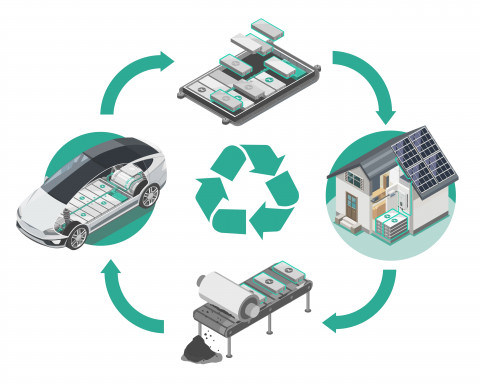

Currently, lithium-ion batteries dominate the EV battery market. These batteries have a finite lifespan, typically ranging from 8-10 years, depending on factors such as usage, charging habits, and environmental conditions. When these batteries reach the end of their life, they can no longer provide sufficient power for driving but they can be repurposed to serve less demanding applications such as stationary energy-storage services (second-life use) or recycled for extracting critical battery raw materials such as lithium, cobalt, nickel, and manganese which could in turn be utilized to manufacture new EV batteries.

Therefore, establishing an efficient and sustainable battery recycling process is paramount. Battery recycling not only ensures safe and responsible disposal of batteries but prevents additional depletion of Earth's rare minerals along with the ecological and human costs involved therein. Moreover, with the growing push for domestic battery manufacturing in the country, battery recycling could help reduce reliance on imports -- strengthening local battery materials supply chains.

Anticipating a surge in battery recycling needs, several Indian companies have now ventured into the battery recycling business. Although the market size is still small, several newcomers are now trying to establish themselves as go-to providers for battery recycling needs -- trying to capture as much market as possible before the industry records explosive growth by the end of the decade.

A few home-grown companies currently active in the lithium-ion battery recycling business are:

Attero - The Noida-based startup is India's biggest lithium battery recycler and a pioneer in the hydromet (mech+hydro) space. It has made significant R&D investments and holds 23 patents in lithium recycling. Attero's patented technology helps it recover more than 98% of lithium carbonate, cobalt, nickel, and graphite from li-ion batteries. The cell chemistry agnostic processes lithium iron phosphate (LFP), lithium cobalt oxide (LCO), lithium titanium oxide (LTO), and various nickel, manganese, and cobalt (NMC) chemistry cells. Attero is said to have approximately 700 tons/year of recycling capacity, which it plans to augment by another 20,000 tons/year of capacity in the next two years. It also has plans to set up large end-to-end recycling plants in other countries like the US, Poland, Indonesia, and Australia in phases.

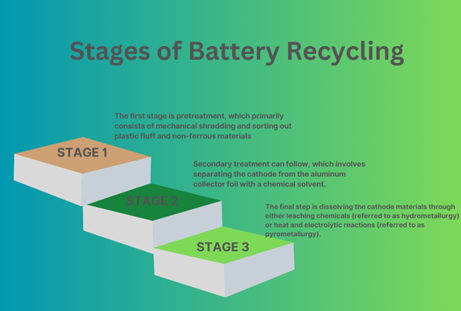

BatX Energies – BatX Energies produces battery-grade materials by recycling end-of-life lithium-ion batteries. At its 4,000 tonnes scraps-recycling plant in Bulandshahr, Uttar Pradesh, the company follows a SPOKE and HUB model that enables it to source end-of-life lithium-ion cells from virtually any geographical location (SPOKE) and transport them safely at the recycling facility (HUB). Through its proprietary mechanical recycling process, it separates black mass from secondary battery parts. It recycles prismatic cells, cylindrical cells, pouch cells and most lithium-ion battery chemistries.

Exigo Recycling – With its recycling plant in Samalkha and Panipat near New Delhi, Exigo Recycling provides recycling services for all types of IT, electronics, electrical, media, and communications equipment. An authorized recycling service provider by the State Pollution Boards & Govt. of India, Exigo is equipped as a Producer Responsibility Organization (PRO) to fulfill all the statutory compliances for producers under Extended Producers Responsibility (EPR). Exigo also provides custom disposal solutions for the collection, reuse, or recycling of consumer electronics products at end-of-life through customized take-back solutions via a group company.

Lohum – With a base in Greater Noida, Lohum is India's only integrated lithium-ion battery manufacturer and recycler. The company claims to be the largest producer of sustainable Li-ion battery raw materials through recycling, repurposing, and low-carbon refining. Lohum recovers critical Li-ion raw materials through its pioneering NEETM recycling technology and recirculates it into the battery ecosystem. The company has the technology and infrastructure to recycle 2 GWh and reuse 300 MWh of battery capacity per annum. Last year, Lohum signed an agreement with the UAE government to build UAE's first EV battery recycling plant. The plant is set to annually recycle 3,000 tons of lithium-ion batteries and repurpose 15MWh battery capacity into sustainable energy storage systems (ESS) per annum.

LICO Materials – LICO is a company focused on recycling end-of-life lithium-ion batteries. With a plant in Panvel, Navi Mumbai, LICO uses a mechanical shredding process to shred spent lithium-ion batteries followed by magnetic separation, vibration screens, and multiple sieving techniques that separate the plastic, steel, aluminum foil, copper foil, and black mass. The black mass is treated using a proprietary hydrometallurgy process that separates compounds of lithium, cobalt, nickel, and manganese. LICO then provides these recovered compounds and battery raw materials back to the lithium-ion battery or cell manufacturer for second-life use.

Nile Li-Cycle – Nile Li-cycle is a leading lead-acid battery recycling company that has forayed into lithium-ion battery recycling. The company recycles lithium-ion batteries of all formats, chemistries, and states-of-charge and processes them through mechanical process, followed by hydrometallurgical processing. Nile has two secondary lead recycling plants located at Choutuppal (60 km from Hyderabad) and at Tirupati (120 km from Chennai).

Li-Circle – Li-Circle provides lithium-ion battery recycling services. With its headquarters in Bengaluru, Li-Circle ensures producers their end-of-life lithium-ion batteries are best used across the value chain and are responsibly urban mined producing zero landfills. Li-Circles recycle lithium-ion batteries irrespective of their type (cylindrical, prismatic, or pouch), battery chemistry, or application (EVs, ESS, portable electronic devices, etc).

Rubamin – Rubamin is a Gujarat-based Group that provides advanced recycling solutions for critical battery materials. The company has decades of experience in hydro and pyro-metallurgy processes and utilizes this expertise for recycling all chemistries of lithium-ion batteries. Rubamin's LIB recycling process enables the recovery of metals such as lithium, nickel, cobalt, and manganese.

Tata Chemicals – Tata Chemicals is a leading chemical recycling company that recently announced its foray into commercial recovery of cathode active materials from spent lithium-ion cells/batteries. Tata Chemicals carries out its recycling operations at a 3P facility located near Mumbai. The operations launched at a pilot scale have successfully recycled spent Li-ion batteries and Tata Chemicals aims to scale it to recycle 500 tons of spent Li-ion batteries. The company's Li-ion battery recycling recovers valuable metals like lithium, cobalt, nickel, and manganese at 99 percent purity.

Ziptrax CleanTech - Ziptrax CleanTech, is a Delhi-based recycling company that provides AI-powered repurposing and patented material recycling for Li-ion batteries. The company reutilizes EV batteries for e-mobility, EV charging, and energy storage applications. The patented technology is used to regenerate and reutilize metals like lithium, cobalt, nickel, and manganese from the spent li-ion batteries for powering future li-ion cells manufactured for use in EVs, energy storage, renewable energy grids, and consumer electronics.