AM Batteries, Amperex Technology Ltd to jointly develop solvent-free electrode manufacturing tech for lithium-ion batteries

Massachusetts-based AM Batteries (AMB) specializing in dry electrode manufacturing for lithium-ion batteries has teamed up with Amperex Technology Ltd (ATL) to develop solvent-free electrode manufacturing technology for lithium-ion cell production.

The standard solvent evaporation process used for electrode fabrication at present, results in high infrastructure costs, heavy carbon footprint, and high energy costs. The joint effort, the companies consider, will help produce key battery electrode components sustainably, enable energy savings, and significantly reduce operational costs.

"The demand for lithium-ion battery continues to increase around the world. One of the fundamental problems for battery manufacturers is refining manufacturing techniques to remove the solvent used in 'wet coating' of electrodes," said Yan Wang, CEO of AMB.

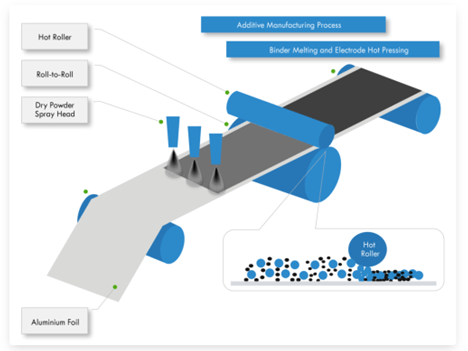

"Our dry electrode manufacturing technology allows for the coating of lithium-ion battery electrodes without the need for any solvents or energy-intensive evaporation."

This platform-technology innovation also offers additional avenues for customization provided by the dry process. The company notes, its technology also offers a path to other benefits, such as faster charging, higher energy density, and safer batteries with current and future battery chemistries.

"We see the need for improvement in battery manufacturing in regard to cost scale and environmental impact issues," said Joe Kit Chu Lam, Executive VP, ATL.

"We have done our due diligence in searching out an innovative company that has a viable solution to these concerns. AMB's electrostatic spray technology directly address these challenges and provide solution for a long-term path for a healthier greener planet."

Owned by a Japanese multinational tech company, TDK Corp., ATL is one of the leading producers of Li-ion batteries. Its expertise in high-tech, high-volume production and packaging of rechargeable lithium-ion battery cells and packs makes the company a suitable partner for developing the latest battery innovation for AMB.

ATL produces batteries for a wide range of applications from smartphones, and laptops, to drones, robots, and wearable devices.