German automaker Mercedes-Benz has announced the signing of a technology cooperation agreement with Taiwan-based ProLogium to develop next-generation battery cells.

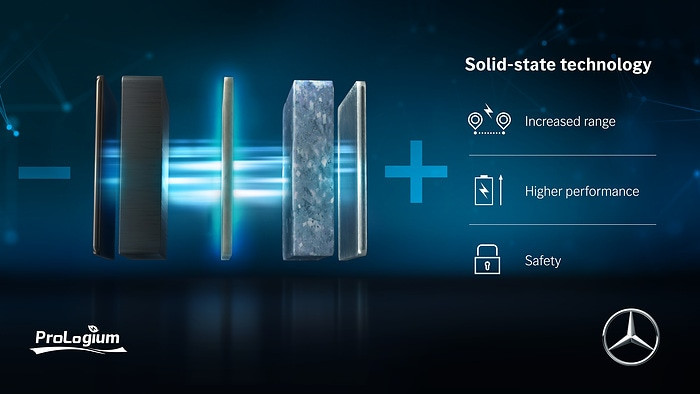

The new partnership is meant to deepen technology cooperation between the two companies, who have also agreed on steps to enable integration of the solid-state battery technology into a range of passenger vehicles in the second half of this decade.

Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG, Chief Technology Officer responsible for Development and Procurement, said, "We believe that range and efficiency are the new industry benchmarks for electric cars. Solid-state technology helps to cut down battery size and weight. This is why we are partnering with companies like ProLogium to ensure that Mercedes-Benz continues to break new ground in the automotive sector - for the benefit of our customers."

Mercedes-Benz plans to go all-electric by 2030 wherever market conditions allow. By partnering with leading companies in the fast-evolving field of solid-state technology, the marque is pushing ahead its R&D activities, fostering further leaps in battery technology, and continuously expanding its network of leading tech partners to ensure access to the most up-to-date technologies.

With its solid-state battery R&D and manufacturing know-how, ProLogium is a strong partner to maintain its role as a leader in battery technology, the company claims. ProLogium is the first battery company in the world to mass-produce solid-state lithium ceramic batteries.

"We have been working with Mercedes-Benz on the testing of our EV battery cells since 2016 and are excited to strengthen and expand our partnership," said Vincent Yang, CEO and Founder of ProLogium Technology.

"We expect to work with Mercedes-Benz to demonstrate the effective application of our safe, high-performance solid-state battery cells to meet the Mercedes-Benz top quality standards. At ProLogium, we believe that innovative technology must be backed by the scalability of production. We look forward to ramping up our new plant by the end of 2022 and working with our customers toward successful mass production", he added.

The automated pilot production line of ProLogium has provided nearly 8,000 solid-state battery sample cells to global car manufacturers for testing and module development. By the end of 2022, the battery firm will complete the establishment of a gigaplant near Taipei, followed by capacity expansion plans in major markets worldwide.

Under the agreement, Mercedes-Benz will take a seat on the ProLogium board of directors. The investment by Mercedes-Benz will be used to support the development of the technology and ProLogium's plan of establishing production capacity in Europe.

Read More