ProLogium opens solid-state lithium ceramic battery plant in Taiwan

Taiwan-based ProLogium Technology has recently launched what it claims as the world's first giga-scale solid-state lithium ceramic battery facility 'Taoke' at Taoyuan in northwestern Taiwan.

With a planned capacity of upto 2 GWh depending on market demand, the facility is poised to supply batteries for up to 26,000 electric vehicles and marks a "new chapter" in the global battery industry, according to the company.

ProLogium further noted that the Taoke plant serves as a demonstration for scaled production and design prototype for its future global expansion, especially the design of the Dunkirk gigafactory that is coming up in France at an investment of € 5.2 billion.

"After 17 years of dedicated effort, ProLogium is thrilled to present next-generation solid-state batteries to the world. The Time is Now," said Vincent Yang, the founder and CEO of ProLogium.

"Our journey has been a testament to overcoming existing technological barriers and innovating new structures, leading to a fundamental transformation in cell structure and process design. We have overcome the bottlenecks in traditional batteries and this breakthrough combines performance, cost efficiency, and resource circulation, manifesting a new universe for the battery industry", he added.

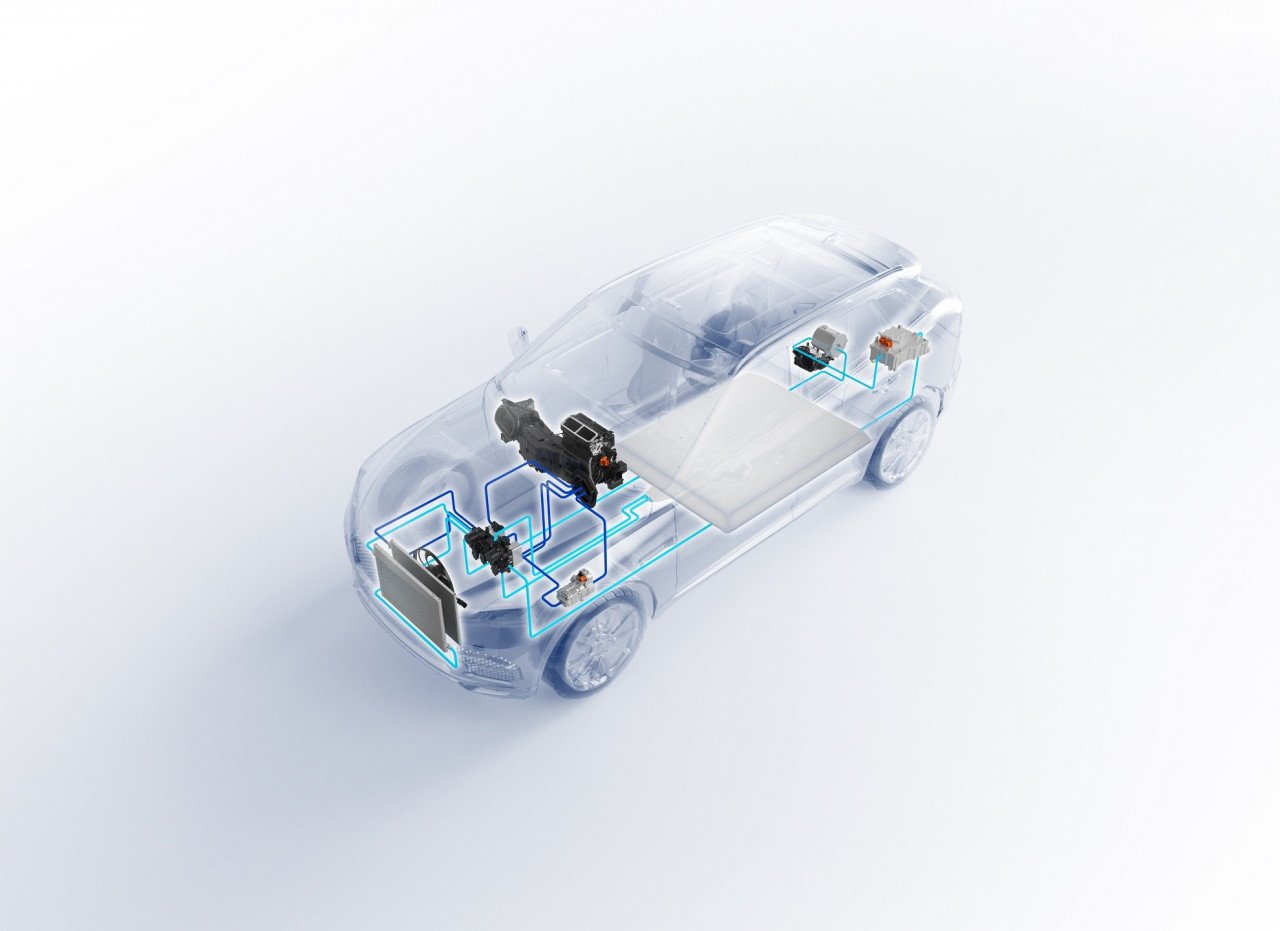

ProLogium, MAHLE partner for solid-state battery solutions

He further claimed that ProLogium is set to globally promote the achievements of the Taoke factory, by propelling the industrialization of solid-state batteries and supporting net-zero ambitions of stakeholders worldwide.

ProLogium claims that its 'Logithium' structure and its patented process have successfully improved the potential yield issue of solid-state batteries, and greatly enhanced the accuracy of alignment and cathode and anode attaching during the manufacturing process.

Currently, the company has achieved a yield target of 99.9 percent for single-layer cells on the trial production line. It is also expanding production capacity while consistently upgrading through process iterations for commercially competitive solid-state batteries.

The Taoke factory's output efficiency is 2.6 times greater than its original facility, with doubled assembly speed and innovative manufacturing technologies, it adds.

For instance, the solid-state electrolytes are indulged in continuous wet coating without the process of liquid electrolyte injection, soaking and degassing, thereby improving production efficiency and quality, with reduced manufacturing costs.

Moreover, the company claims to have successfully overcome the challenges that solid-state batteries have faced in terms of mass production and economics. Reaching a scale can help lowering the manufacturing costs to the same level as mainstream batteries, it opines.