IESA organizes 2nd edition of India Battery Manufacturing and Supply Chain Summit 2022

As a vibrant platform to discourse on the state-of-affairs of the entire battery manufacturing and supply chain ecosystem, the India Battery Manufacturing and Supply Chain Summit 2022 (IBSCS) targets to make India a manufacturing hub and a lead supplier in the global battery supply chain landscape by the end of this decade.

Energy storage is increasingly recognized as a key enabler for cleaner and greener energy transition across the globe. Accelerated threats of climate change are pushing governments and businesses towards mass adoption of battery energy storage technologies in a plethora of sectors, especially in transportation, power generation, and distribution. Hence, there is immense demand for batteries in the global markets, and this demand is bound to grow multi-fold in the coming year.

The second-edition of India Battery Manufacturing and Supply Chain Summit 2022 (IBSCS) is held at the backdrop of the National Program on Advanced Chemistry Cell (ACC) battery storage launched last year, in which three companies have signed the production-linked incentive (PLI) agreement to kick-start the process of building ACC battery giga factories in the country. India, being a manufacturing hub for several industries including automotive and components, naturally targets to become a reputable player in battery manufacturing and supply chain at the international level.

IESA, as a premier industry alliance promoting clean energy technologies, is working at various levels for the development and maturation of the domestic battery manufacturing and supply chain ecosystem in India. The latest summit is one such effort to bring all the stakeholders in the battery supply chain together to identify and discuss opportunities and challenges to churn out a roadmap for the country to excel in its battery manufacturing ambitions.

"Although a lot has happened in the creation of the domestic battery manufacturing landscape in recent times, we are still observing gaps and inaction in various aspects, especially in the manufacturing and deployment side, thereby hindering the growth of the industry", said Debi Prasad Dash, Executive Director, IESA at the summit. "The India Battery Manufacturing and Supply Chain Summit tries to capture all such critical points that needs to be addressed for further policy action and deployment".

Debi also spoke on IESA's India Battery Supply Chain Council (IBSCC) and IESA Reuse and Recycling Initiative (IRRI) initiatives to support the battery industry in various aspects of indigenous manufacturing. "We need to develop a robust supply chain to achieve our set targets, while the long-term focus has to be on the entire spectrum of activities from raw materials to recycling", he added.

In his opening remarks, Dr. Rahul Walawalkar, President – IESA, said that goal for India is to capture at least 10-20 percent of the global supply chain for battery manufacturing by 2030 and 2035. "Although China is bound to continue dominating the battery manufacturing and supply chain, the global market is to increase four times during the period. Thus, even a 10-20 percent target represents an opportunity for India to set up a supply chain for 500 GWh by 2030 and 2000 GWh of annual production by 2035".

He opined that the kind of investments and R&D will play a key role in deciding the outlook for the battery industry. "There is immense opportunity for a variety of cell chemistries and battery technology, also for different types of battery materials and components – not just anode and cathode materials. Focus has to be on the mid-stream and up-stream of the supply chain ecosystem", he noted.

Walawalkar also called for the industry to be more aspirational and pro-active in coming together to address the critical concerns of the battery manufacturing and materials supply chain in India. "We need to take benefit from the experiences of the European and North American battery manufacturing landscape. There is capital available for investments in clean technologies, while the policy support is emerging as well. We have a much better chance and opportunity to emerge as a global supplier in the coming decade", he said.

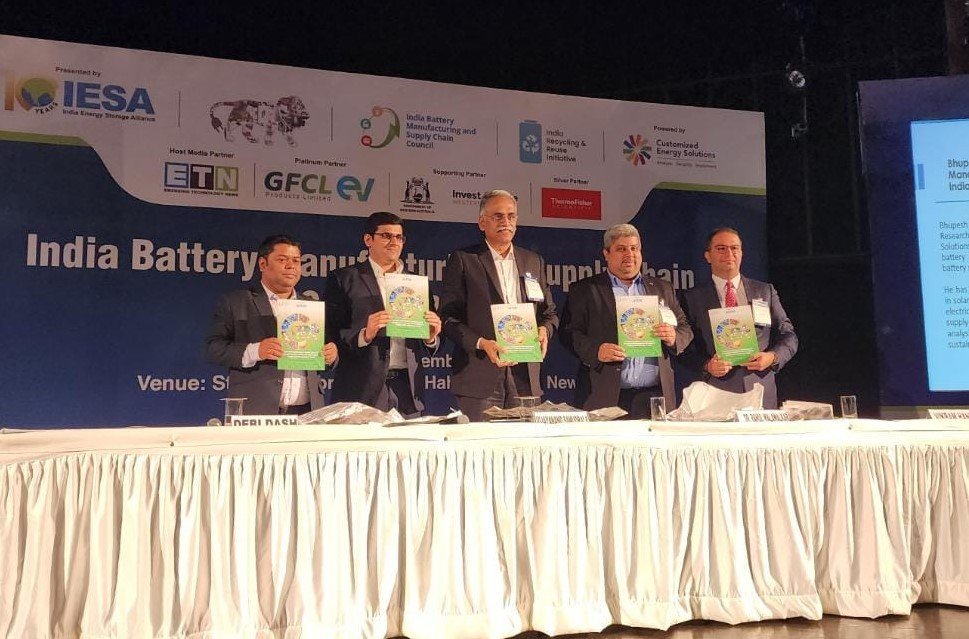

At the Day 1 of the summit, IESA launched a knowledge paper by India Battery Supply Chain Council (IBSCC) titled "Policy Recommendation on Devising Special Incentives for Supporting the Battery Supply Chain Industry in India". The alliance also inked a MoU with the Association of Renewable Energy Agencies of States (AREAS) at the summit.

Speaking at the inaugural session, Vikram Handa, MD, Epsilon Advanced Materials and Chair of IBSCC, said the summit is a real opportunity for the companies in the battery supply chain explore new opportunities and evolve standards, especially in terms of ESG impacts and best-in-class manufacturing. "IESA has played a key role in recognizing the battery materials suppliers in India", he remarked.

Vijayanand Samudrala, President – New Energy, Amararaja Batteries, commented that IESA platforms are extremely important for the addressing the battery material supply chain and larger ecosystem concerns, as no individual companies or agencies can find a way out on their own. He identifies four critical challenges to scalling-up of call manufacturing in India, namely – technological uncertainty, supply chain limitations, limited local R&D capabilities, and skilled manpower for executing giga factories.

RELATED: IESA to collaborate with DST for Research and Development Fellowship Program