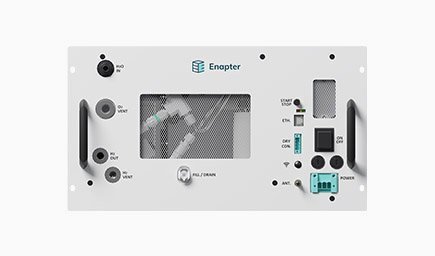

Enapter begins production of EL 4.0 LC water-cooled AEM Electrolyzer

Enapter AG has commenced the production of its new, water-cooled variant of its AEM Electrolyzer EL 4.0, expanding its product range with a new standardized device. The company claims that the new product enables the direct connection of an external cooling system to optimize thermal management and make efficient use of waste heat.

The manufacturer further adds that the electrolyzer is particularly suitable for producing green hydrogen at locations and operating sites where, due to external conditions, sufficient cooling by means such as exhaust air systems is not possible, and in systems where customers wishes to use the waste heat produced more efficiently.

The heat is released via a secondary circuit and can be combined with a heat pump. A common cooling circuit with other components such as water-cooled fuel cells is also possible. Enapter says that due to the external water cooling, this electrolyzer offers the best conditions for installations in smaller rooms and containers.

Moreover, the dissipation of heat through external pipes proves particularly effective when combining several EL 4.0 LC units in a cluster. Thus, at different coolant inlet temperatures, between 600 W and 900 W of heat (with an increasing trend from the beginning to the end of life) can be extracted from each unit and made available for external applications.

RELATED: Enapter to supply AEM electrolyzers for 12.5 MW hydrogen pilot in South Korea

With the new water-cooled AEM Electrolyzer EL 4.0, the company stays true to its successful modular approach. Like the air-cooled variant already in production, the new product is also easy to integrate and simple to scale for systems of different sizes depending on the application requirements.

The combination with an external cooling circuit also increases the degree of flexibility on the user side and makes it possible to create an individual setup that can be perfectly matched to the needs of demanding customer groups, according to Enapter.

The AEM Electrolyzer EL 4.0 LC is offered in both AC and DC versions. The current delivery times for the EL 4.0 range from 2 to 12 weeks on average, depending on the order size. Enapter claims to have already received the first orders for the new variant.