Comau, LiNa Energy innovate solid-state sodium battery manufacturing process

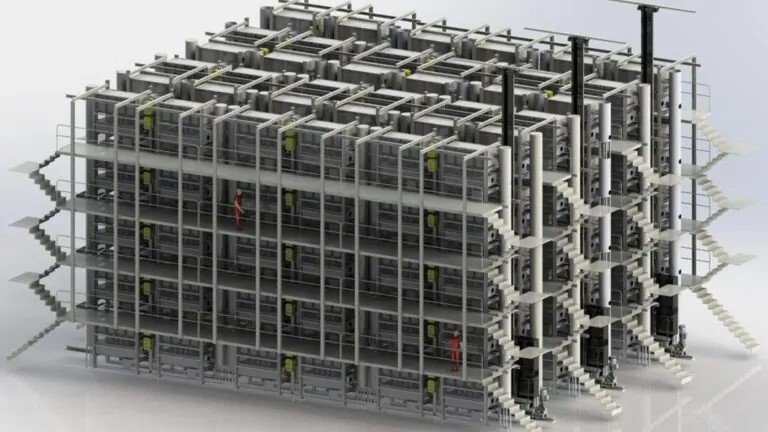

Automation solutions company Comau has joined forces with battery manufacturer LiNa Energy to design an innovative and scalable manufacturing solution for solid-state sodium-metal-chloride battery cells. Through simultaneous engineering, the team has recently finalized a concept design, allowing LiNa to automate their battery production process.

The companies intend to validate the sustainable, safe, and efficient oxygen-free dry box environment as a step towards larger-scale manufacturing. Comau and LiNa engineers worked in tandem to design the enclosure and handling equipment for the specific components of the solid-state battery cell.

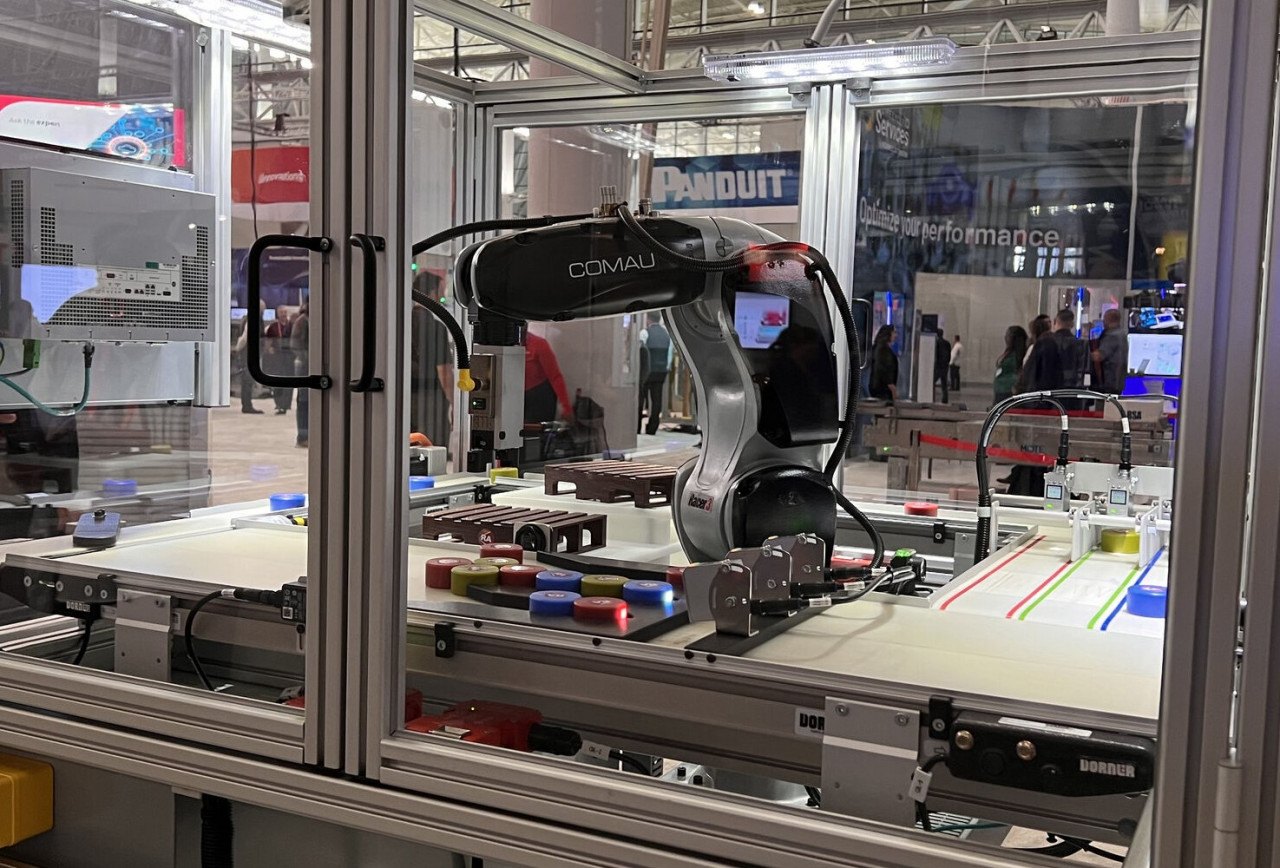

Further, they have rightly identified and integrated existing commercially available equipment, including Comau's 'Sensitive Environments' articulated robots into their system design. This collaborative approach has enabled Comau to suggest modifications to LiNa's existing manufacturing methodology with the aim of optimizing process dynamics in the move to automatic cell assembly.

"This automated manufacturing concept, designed with Comau's engineering team, provides a clear technology roadmap to significantly increase production capacity of our patented battery cells", commented Kris Barr, LiNA Director of Operations.

Comau developing innovative battery cell formation solutions for GIGABAT project

"Having successfully researched the process dynamics and finalised an innovative design proposal, we are looking forward to taking the next steps in our mission to commercialise our sustainable, low-cost solid-state sodium batteries. This approach not only ensures progress and cost control but also guarantees the quality, performance and reliability of the final product", he said.

With this, Comau's solutions cover the entire battery manufacturing value chain from cell formation through end-of-life recycling. "Our steadfast commitment to energy transformation is a perfect match for a company like LiNa, whose vision and engineering competence are promoting and enabling the development of high-performance sodium-based energy storage solutions", said Gian Carlo Tronzano, Comau Head of e-Mobility Global Competence Center.

Comau claims to have provided LiNa with a detailed technology roadmap to automate their innovative cell manufacturing process. Furthermore, leveraging its ongoing development of new manufacturing technologies for next-generation battery cells, the company boasts a 360-degree 'cradle-to-grave' e-mobility strategy.

Recent developments in sodium-based battery cell technology are driving the deployment of a safe, sustainable energy source that can be used at high temperatures. Experts say that the next-gen solid-state sodium batteries can provide high performance energy storage that is both cost efficient and optimizable for renewable energy integration in developing markets.